Benefits of Split /Splitless Injection in Capillary Gas Chromatography

Before we move on to the benefits of split/splitless injection in capillary gas chromatography, let’s see a few details about these two injections.

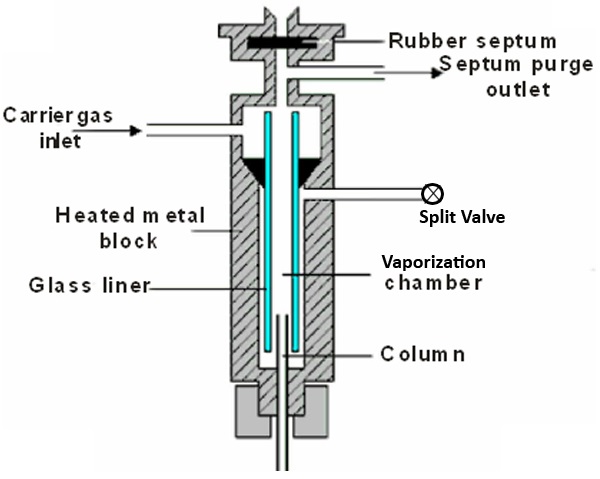

Split Injection

The reason why split injections are more popular than splitless ones is that they are versatile enough to be used in a number of diverse analyses. It comes with a split ratio, which describes the amount of gas that will split through the different parts of the injection. This ratio can range anywhere between 5:1 to 500:1, and you can fix it prior to analysis as per your individual application and requirement.

The lower value of the ratio describes the amount of gas that passes through the available column inside the injection. On the other hand, the higher value is for the amount of gas that leaves through the split vent. So you can determine the ratio accordingly.

Splitless Injection

Splitless injection GC is yet another commonly practised injection method. The overall design of this injection is similar to that of the split variant. However, there is one minor difference, i.e., the split vent is closed here before and while the injection of the sample takes place. That is why it is named as the “splitless” injection, as it lacks the split vent.

The split vent is only opened after the predetermined duration of the injection. This brings in several differences in the overall process of gas chromatography. The most crucial parameter of the splitless variant is its splitless time. You must understand that before moving forward with the comparison of the two injections.

Splitless Time: This is the time span for which the split vent is kept closed during the process. It has to be precise. If the duration is kept small, the entire sample won’t get transferred to the column, and the process won’t take place correctly. Contrastingly, the extensively longer splitless time can also result in complications. That is why it must be set, appropriately, while keeping all the factors in mind. In most cases, the duration is kept between 20 seconds to 1 minute.

Split vs Splitless Injection

Most people are often confused between which injection technique they should use for their purpose. The split vs splitless injection comparison can be done based on a few factors:

- Sample Concentration: Split injections bring in on-instrument dilution. Therefore, only high concentration samples can be used in this method so that the required detection limits can be met without any problem. On the flip side, you will have to go with a splitless injection GC if the available sample concentration is quite low.

- Injection Speed: The speed of injecting the sample differs significantly in both methods. It is kept high in split injections to avoid injection band’s dispersion. However, the injection speed is kept slow for split injector splitless mode so that the complete vapourised sample will fit conveniently into the liner. This usually brings in a difference in the sensitivity of the used detector.

You need to keep both these factors in mind while choosing the correct injection method for your gas chromatography.

Benefits of Split/Splitless Injection

Benefits of split/splitless injection in Gas Chromatographic detection gives you the freedom of changing the amount of sample component entering the capillary column.

|

At times you may get a broad flat top peak instead of a sharp well-defined peak. In such situations you have the following options available:

- Dilute the sample

- Attenuate the signal

- Use split mode injection

The first two options are hit and trial manual exercises and often take up substantial amount of valuable time.

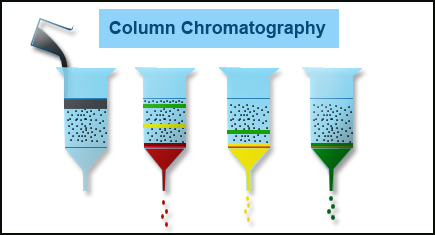

In the split/splitless mode using software control a valve changes the proportion of the injected sample component that would reach the column head. Split valve controls the amount of sample entering the column, say in the proportion 100:1, i.e, for every hundred parts only one part enters the column and the remaining part is vented out. The settings can be stored in the analytical method for getting reproducible analysis every time.

The split mode achieves online dilution of the sample without the need for adding diluting solvent to the injected sample. This holds for analysis when the concentration of sample component overloads the column and results in a broad peak. We shall now look into a situation where the components of interest are present in trace levels. The classical approach would be to pre – concentrate the sample before injection which is again a time-consuming activity.

Resorting to split test mode through the software will shut the split valve in a programmed manner to permit majority of the sample to reach the column. This will result in enhancement of peaks of trace components.

We have seen that the split/ splitless injection mode offers you the benefit of analysis of sample components over a vast concentration range without the need for time-consuming sample dilutions or pre-concentrations. All modern PC systems provide this facility at the simple click of the software.

After going through the article you will like to share your experiences on working over a vast range of concentrations of components and impurities of your interest.

Sir,

I extend my sincere greetings and thanks for the wonderful and informative articles posted regarding various analytical techniques. May I request you to bring out articles on easy techniques adopted for sample extraction, concentration and the different solvents / techniques used for the analysis of pesticides in water samples using GC

Thanks and Regards

Anita

Very nicely explained .. experience beyond books

WELCOME Dear :-)