Influence of changes in operational conditions on Gas Chromatograms

Gas Chromatography contributes significantly in testing and quality control laboratories in petrochemicals and fuels, foods, pharmaceuticals, flavours and fragrances and cosmetics industries. The technique offers high sensitivity and even minor changes in operational conditions have a marked bearing on chromatographic outputs. Such changes can lead to misleading interpretations and conclusions based on observations.

The article covers some of the common changes resulting from operational conditions and steps that can be taken under such circumstances.

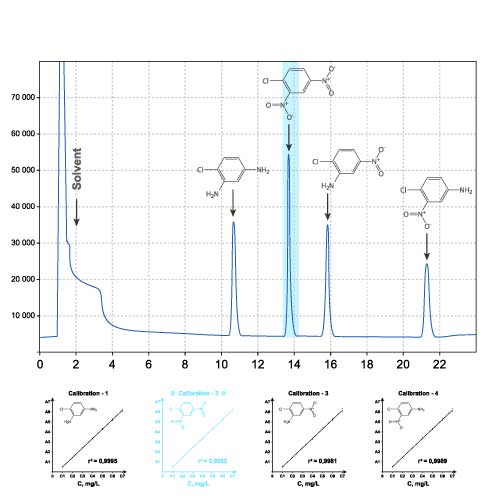

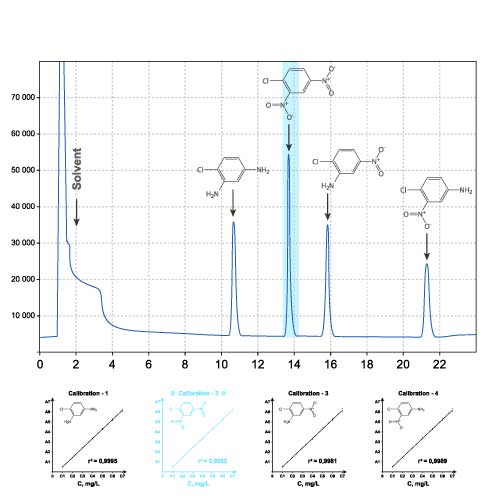

Standard Calibration mixture injection

After the system stabilizes after set up it is advisable to run a standard injection. It should be repeated again after 2-3 sample injections to confirm that there is no change in operating conditions or column performance.

The peak position and response for calibration mixture components should remain unchanged so that reliance can be placed on sample response. It goes without saying that the instrument’s calibration should be valid on the date of analysis.

Unexpected Peaks

Several factors could be responsible for appearance of unexpected peaks. Such peaks can arise on account of :

- Impurities present in carrier gas

- Remnants of earlier samples analyzed in syringes, columns or detectors

- Sample degradation prior to injection due to improper storage conditions or degradation of sample components in column oven due to high temperatures

- Loss of volatile sample components prior to injection

Retention Time shifts

Common reasons for retention time shifts of peaks are fluctuations in flow rate of carrier gas or set temperature programs. In severe cases some late coming peaks can even move out of the chromatograms which can lead to erroneous conclusions. Special care is required to ensure that there are no fluctuations in the set operating conditions.

Such changes can also result from leaks at fittings and joints. Leaks can lead to flow rate changes in addition to introduction of oxygen into the column which has potential of causing damage to the stationary phase at high oven temperatures. It is therefore essential to monitor leaks. Today most operating softwares offer built- in leak detection features.

Peak shape distortions or appearance of shoulder peaks

Peak shape distortions often lead to peak broadening, peak tailing or fronting and appearance of shoulder peaks. Such changes result from changes in operational conditions or presence of impurities. The solution lies in careful control over such conditions and freedom from leaks .Alternately it may become necessary to replace the column or switch over to another suitable detector.

It is always advisable to perform system suitability testing before undertaking analysis. System suitability testing confirms that the selected system configuration and method adopted are suitable for the intended purpose of the analysis.

Responses