Sample Injection Techniques for Capillary Column Gas Chromatography

Whenever you inject a sample into a Gas Chromatograph you are dealing with small micro- volumes of liquids which can be mixtures with differing volatilities in terms of their boiling points and other chemical characteristics. The desirable feature of the sample injection technique is reproducibility of injection volume injection after injection without loss of any component.

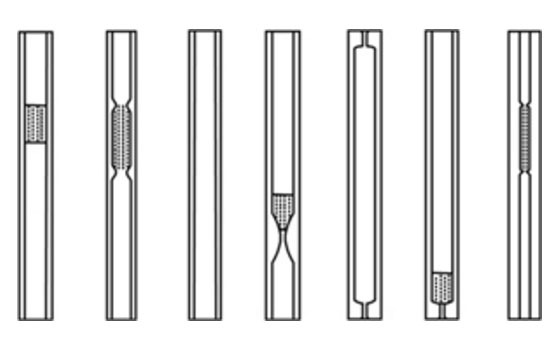

Several approaches are in use for efficient and reproducible transfer of the injected volume through a syringe or auto sampler. A liner serves as the sample transfer link between the injector and the column. Four injection techniques are commonly used:

- Split less injection

- Split Injection

- Direct injection

- On- Column injection

The salient features of techniques are briefly discussed below:

Splitless Injection

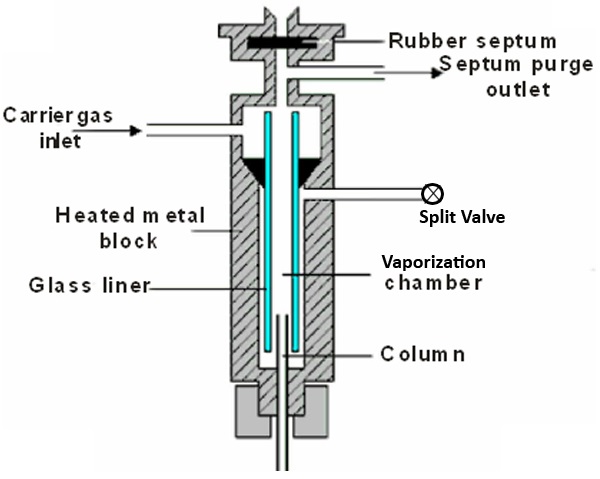

The sample on injection gets evaporated inside the heated liner. At this stage the split valve of the split- splitless injector is closed and the injected sample is transferred to the column by the carrier gas flow. After a majority of the sample is transferred the valve is opened and the sample moves to the column during the time the split valve is in close position. The optimum splitless time should be matched with the maximum of the eluting component peak. Selection of too low splitless time results in loss of sample leading to poor detection limits. If the time selected is too long traces of solvent can give rise to tailing peaks. As the residence time of the sample in the liner is longer than in the split mode there is no need to use a liner design that leads to high turbulence. However, as the residence time is longer use of the deactivated liners is recommended. Sample adsorption on the active sites on liner can lead to tailing of peaks or poor sensitivities due to loss of injected components.

Split Injection

The design of split liner ensures turbulence which leads to improved vaporization and mixing of sample vapour with carrier stream prior to splitting. The split results in a limited amount of sample reaching the column thereby preventing overload of capillary columns and fronting of peaks. Only a small portion of the sample is allowed to reach the column and the other is vented through the open split valve.

The split ratio is the ratio of the flow rates of the split vent flow and the column flow. Normally split ratios are in the range of 100:1 to about 20:1. For wide bore or thick film columns low split ratios are used whereas for narrow bore high-speed chromatography columns higher split ratios can be used.

Split analysis cannot be used for trace determinations due to loss of sample. Further some sample degradation can take place on glass wool or frits used inside split mode liners. However, due to its ruggedness and ease of use it is a widely used technique.

Direct Injection

Direct injection offers higher sensitivities when gas phase samples are to be analyzed .Common applications include headspace analysis, purge and trap and solid phase micro-extraction techniques. The entire gas volume gets transferred to the column. As there is no solvent present there is no increase in volume due to solvent expansion.Narrow bore liners 0.5 to 1.5 mm id help maintain high linear velocities and a minimum of peak broadening.

On-Column Injection

On-column injection is the preferred technique when the liquids present in the sample have widely differing boiling points. The liquid sample is introduced directly into the inlet of a wide bore (0.53 mm) capillary column. The liner used has a tapered design which acts as a seal between the column and the liner and also helps guide the needle into the column. The injection technique is used in temperature programming mode wherein the oven temperature vaporizes the sample.

The on-column injection technique offers several advantages for trace analysis as larger sample volume can be injected, there is no loss of samples by degradation on hot liner surface and freedom from loss of sample as in split mode.

The liner design plays a significant role in different injection techniques. Different injector liner designs will be discussed subsequently.

Responses