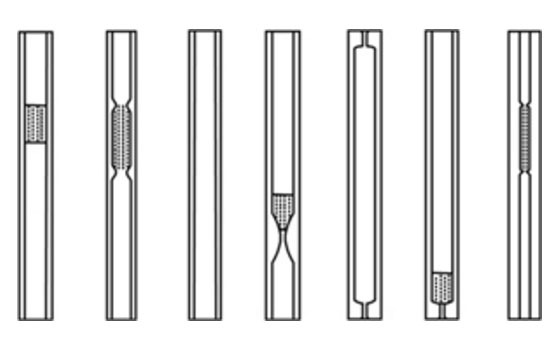

Types of Liners and their Selection

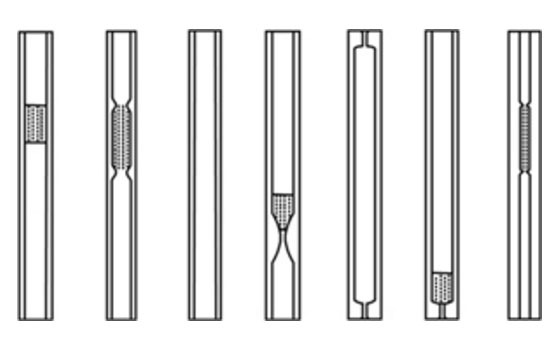

A GC inlet liner plays an important role in transfer of the injected sample into the GC column. It provides an inert surface for conversion of the injected liquid sample to vapour and transfer to the column without any change in its characteristics.

Liners are available in different design configurations with or without deactivation and with optional packings. The choice of a liner is based on the sample type and type of injection technique adopted. The topic covers the suitability of different liners for different injection techniques.

Selection Based on Type of Injection

Split Injection

Split injections are adopted when analyte concentrations are high and low level detection is not necessary. Such injections are made at higher flow rates and part of sample is led out through the split vent. The sample vapour spends less time in the liner. Such liners require rapid vaporization. Glass wool filled liners are chosen as they provide increased surface area and the injection needle is wiped during injections for improved repeatability. An unpacked liner should be preferred when analyzing active samples such as pesticides. In such cases glass wool packing can lead o formation of breakdown products.

Splitless Injection

Splitless injections are useful for trace level analysis. Preferably use a deactivated liner and use of deactivated glass wool will improve analytical performance. The wool helps concentrate the sample from where it can vaporize. Further it prolongs useful life of a column by preventing nonvolatile sample components from reaching the column. The position of glass wool can assist in improvement of sample transfer. Injection reproducibility is improved by transfer of the injected sample into the glass wool as the needle tip is wiped every time on removal. Displacement of glass wool plug can be restricted by positioning it between baffles inside the liner.

Unpacked liners can be reused after cleaning but the cleaning process can lead to increased surface activity and contribute to poor performance.

Direct Injection

Direct injection is used when trace level determinations are required and then there is a possibility of degradation of active sample components. The sample is injected directly into a hot inlet to allow the entire sample to be vaporized into the GC column. Such liners usually come with a press-fit connection at the bottom which fits and makes leak free contact with the column. Such liners have a hole drilled either at bottom or top. Semi-volatile compounds are analyzed with bottom hole liners and for aqueous solvent samples top hole liners give improved results.

Programmable Temperature Vaporization (PTV) Injections

The sample is injected into a cold inlet which is then subjected to a heating program leading to the vaporization of the components for introduction into the column. PTV liners have small inner diameters and are provided with baffles to introduce turbulence and rapid heat transfer of sample to the column.

In summary the choice of a liner is dependent on the injection technique selected. Liners with deactivated surfaces and deactivated glass wool packing can be used safely for most applications involving active components. However, for very sensitive compounds use liners without glass wool packings. For gaseous samples where there is no need for vaporization the liner is required to efficiently transfer the sample to the column. A narrow bore liner of 1.0 mm id is recommended for introduction of the sample as a sharp band into the column.

excellent training

VERY VERY HELPFUL TIPS FOR SELECTING GC LINERS.

THANKS