Sample Injection Practices in Gas Chromatography

The accuracy and reproducibility of your Gas Chromatographic analysis will depend to a great extent on the technique adopted for sample injection. Gas chromatography in contrast to liquid chromatography involves analysis of both liquid as well as gaseous samples. This places more stringent requirements on accurate measurement and transfer of injected volumes.

Syringe Injection

Syringe injection is an adopted practice in majority of chromatographic applications. Factors governing choice of sample injection syringe in gas chromatography covered the different types of syringes used for making sample injections. Greater degree of accuracy and precision of injected volumes is possible through proper use and handling of chromatographic syringes. Some useful tips and guidelines are covered in the article Proper use, handling and care of chromatographic syringes.

The injected sample should not be too large in size and should enter the column as a plug of vapour so as to avoid loss of resolution due to band broadening.

A micro syringe injects sample through a rubber septum into a Flash vaporiser. The temperature of the sample port is usually about 50°C higher than the boiling point of the lowest boiling component of the sample mixture. The injection volumes generally range between 0.5 to 5μl. The precision of syringe injections is around +/-1%. The split- splitless mode of injection is commonly adopted in capillary gas chromatography.

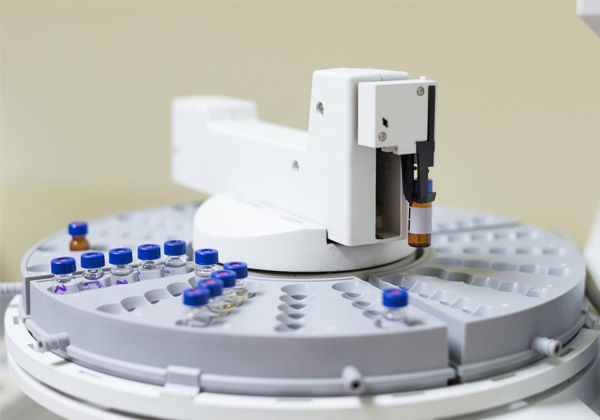

Autosampler Injection

It is basically a syringe injection technique for laboratory gas chromatographic analysis. The samples are loaded in the desired sequence in the autosampler tray in sealed vials and standard sample vials are interspersed in the tray as per analysis requirements. The operational software controls sequence of injection, sample volume, number of wash cycles and injection sequence for standards and samples. The key benefit offered by autosampler is freedom to do other tasks while the analysis is in progress.

Programmable Temperature Volume (PTV) Injection

Programmable temperature volume injector permits introduction of larger sample volumes for greater sensitivities. The liner temperature is kept below the boiling point of the solvent which permits continuous removal of solvent through the split line.In addition to large volume injection the potential degradation of sample components due to low liner temperatures is achieved.

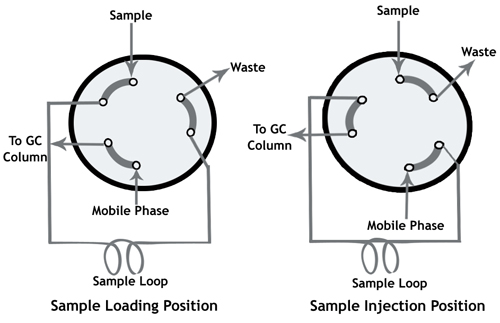

Gas Switching Valves

The greatest advantage of gas switching valves is elimination of personal errors in sample volume take up as in the case of the syringe injections. Further the carrier gas flow is not interrupted while sample is being introduced into the empty sample loop. Upon switching the valve the contents of the sample loop are introduced into the carrier gas stream. Sample volumes can be introduced reproducibly by making use of injector valves which can be operated through either manual or automatic control.

Gas sampling valves provide at least ten times higher precision of injection (+/ -0.1%) in comparison to syringe injection. Multiport valves are in common use in dedicated gas sampling applications such as petroleum and refining analysis and flavour/fragrances in food and cosmetic industries. However, in routine laboratory applications six port valves meet the required accuracy and precision of results.

In suimmation the accuracy and precision of your results will largely depend on reproducibility of injection volumes, freedom of syringes and sampling loops from traces of earlier samples and condition of columns.

Responses