Distillation and Reflux Condensers

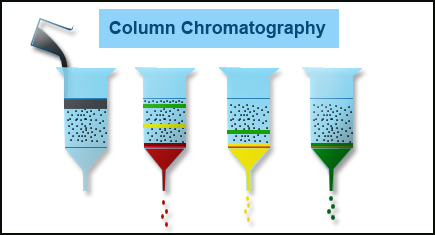

Distillation and Reflux heating are common laboratory operations. Distillation becomes necessary when you have to isolate a pure solvent from a mixture of several other solvents based on the differences in their boiling points.

The types of commonly used laboratory distillations have been covered in How to select the optimum laboratory distillation technique. In contrast to distillation the process of reflux in involves heating of the reactants in a flask and through condensation the return of condensed liquid back to the heating flask. This operation is useful in preventing loss of solvent thereby increasing the reaction time over which the flask can be heated.

From a broader perspective, both distillation and reflux may seem the same type of procedures where a solution is boiled and condensed. However, their purposes are entirely different. Where the prior helps with separation of mixture components, the latter one assists in completing a specific reaction. That is why we need to study the use of distillation and reflux condensers independently. Let’s first see how a condenser is used.

What Is the Purpose of a Distillation Condenser?

The distillation process is based on the concept of boiling points, which is different for every liquid. So when you boil a mixture, the lower boiling point fluid evaporates while the other one stays in the flask. The component that turned into vapours is then collected in a condenser to convert it back into the liquid form.

In simple terms, we can also state that distillation becomes necessary when you have to isolate a pure solvent from a mixture of several other solvents based on the differences in their boiling points. In the entire process, a condenser helps in bringing the component back into liquid form gas.

Distillation can be further divided into four types:

- Simple Distillation: In this, two liquid components are separated, given a significant difference in the temperature at which each of them converts into vapours.

- Steam Distillation: Instead of liquids, heat-sensitive components get separated in this.

- Fractional Distillation: Crude oil’s hydrocarbon fractions are separated by this process.

- Vacuum Distillation: This procedure is utilised for the substances that have extremely high boiling points.

However, a condenser is used for the same purpose in all of them.

What Is the Purpose of a Reflux Condenser?

Unlike distillation, the reflux process is used in chemistry to accelerate a specific reaction thermally. This is done by conducting it in a controlled high temperature. The role of a condenser here is to cool down the generated vapours and convert them back into the liquid form. The liquid component is then sent back to the boiler. So the reflux condenser purpose is to stop the loss of solvent, thereby increasing the reaction time over which the flask can be heated.

Reflux vs Distillation Condenser Difference

Distillation in comparison to refluxing is a much simpler operation, and a simple condenser serves its purpose. That is why usually Liebig condenser is used for the process.

This comprises two straight and long concentric tubes which are sealed at both ends. The vapour from the flask moves along the inner tube and condenses due to circulation of water in the outer jacket. Apart from the tubes, rubber stoppers are used to connect the apparatus to other components of the setup. After conversion, the condensed liquid is collected in another container.

On the other hand, a reflux condenser’s job is a bit complicated. It has to stop the vapours from escaping while converting them into liquid. It also has to provide a restriction-free passage for the liquid to return to the reaction vessel. Plus, this process goes on until the reaction gets completed. That is why it requires a more advanced condenser.

Types of Reflux Condensers

Basically reflux condensers fall into two categories, namely, Graham type and coil type. In Graham type of condenser vapour flows through the central tube and condenses along its walls to flow back into the reaction flask.

In the coil condenser water as a coolant is passed through the central coil and the vapour moves along the larger outside jacket. Graham type condenser suffers from a major limitation of frequent clogging as the condensed liquid has to return to the reaction vessel through a narrow restricted path. A few general types of reflux condensers are:

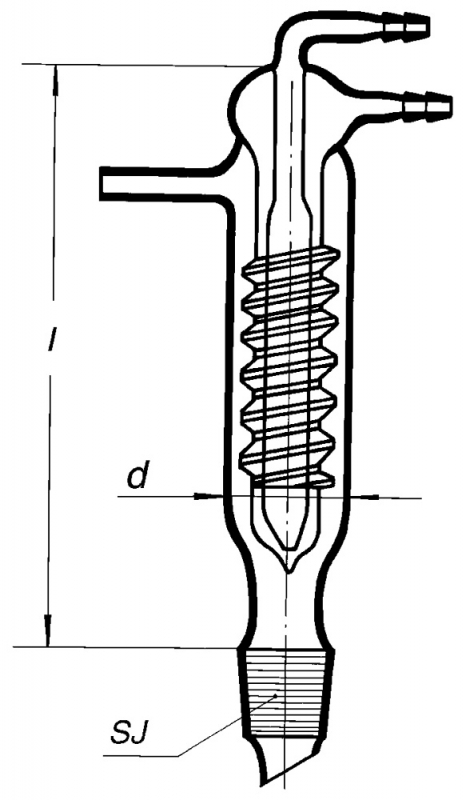

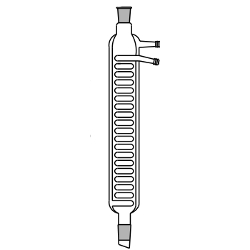

Allihn Condenser

The Allihn condenser is also known as a ‘bulb condenser’. It consists of an outer water glass jacket. The central tube comprises of a series of bulbs that provide increased surface area for condensation of the vapour. It is an improvement over Graham condenser as the condensed liquid flows down along the bulb walls thereby avoiding blockage to the rising vapour. It also provides a wider bore at the bottom so it is useful for reflux heating when mounted vertically.

Where an Allihn condenser is highly preferred for reflux, it does not serve the purpose of distillation. In the latter process, it may get the substance trapped on bulbs’ sides, especially in the horizontal position. That is why it is better to keep it with reflux processes only.

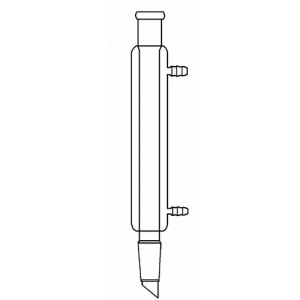

Davies Condenser

Another name to the list is a Davies condenser. It is functionally similar to the Liebig condenser but it comprises of three concentric glass tubes. The coolant circulates both in the outer jacket as well as the central tube. The vapour condenses on the inner tubes and flows down into the reflux flask. The condenser is suitable for condensation of vapours over a broad range of boiling points including low boiling volatile liquids.

A few benefits of Davies condenser are:

- It provides an extensive cooling surface.

- “Baffle effect” can be found in its inner cooling surface.

- “Creeps” can be avoided with the help of the outer cooling surface for all low boiling point liquids.

Jacketed Coil Condenser

It is similar to Davies but instead of a straight inner tube it is a coiled tube. This provides improved performance over the Davies condenser due to increased surface area to facilitate condensation. Plus, the size remains compact, providing more benefit. So these are considered better than the usual Davies condenser.

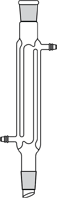

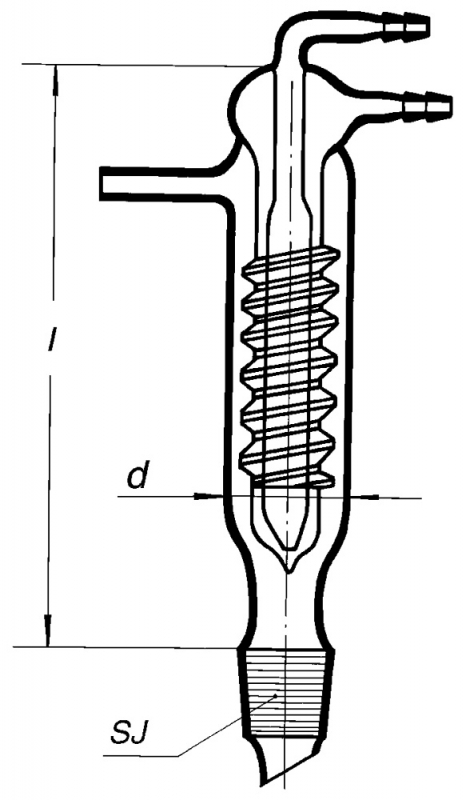

Dimroth Condenser

A Dimroth condenser has double internal spirals. The coolant inlet and outlet are both at the top. Vapour travels from bottom to top. Such configuration is even more effective than traditional coil condensers.

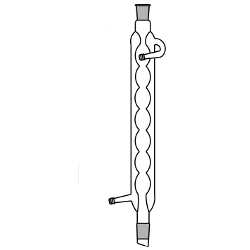

Friedrichs Condensers

Fredrichs condensers consists of a spiral internal cold – finger type capillary within a cylindrical housing. Coolant is made to flow through the internal cold finger and vapours rise along the spiral path. Such condensers are suitable for both distillations and reflux reactions.

How to Select a Condenser?

Now the question arises that with the availability of such a wide range of condensers which is the best option. Your choice should be based on your requirements and you would obviously like a good compromise between performance and price. It is a good decision to buy a condenser that will work both for distillation and reflux reactions.

The Friedrich type proves useful for challenging distillation applications and can be used in a sequence with the Liebig condenser.

Reflux applications are mostly covered with Allihn but Dimroth and double surface coil condensers can prove beneficial for efficient recovery of large quantities of generated vapours and maintain a constant solvent composition in the reflux flask.

Therefore, you first need to check the usability of the condenser. If there are certain features of it that do not allow you to use it for either of the processes, you may want to go for some other option. Once you are satisfied with the purposes that it solves, you can move on to price comparison. It is crucial to maintain that balance as you will not want to spend all the money on just the condenser.

Plus, you need to remember here that high cost does not guarantee good performance. So it is better that you compare the features first and then relate the price.

Super sir