Importance of Gas leak detection before starting Gas Chromatographic Analysis

As a standard practice before starting GC operation gas leaks, if any, should be detected and rectified

Why check for leaks?

In any situation there is possibility of two types of gas leakages, namely, major leaks or minor leaks.

Major leakages can result from cracked columns, damaged and loose fittings or ferrules or more commonly if a column or detector connection is not made through oversight. In such case most systems will automatically shut down

Minor leaks are more common and result from loose fittings, damaged ferrules, cored septa or broken fittings due to over tightening of nuts. Minor leaks do not lead to instrument shut down but present following problems:

- Drifts and poor reproducibility of peak areas

- Unstable baseline due to larger background noise

- Irreversible damage to column packings, particularly if exposed to oxygen at higher temperatures

- Increased detector maintenance

- Reduction of lifetime of traps

- Higher: bleed at higher temperatures (>230°C)

All such problems can be avoided and valuable time can be saved if leak checking is made a standard practice before start of GC analysis

How to check for leaks?

Pressure Drop

The simplest method for detecting leaks is by observing for any significant pressure drop over a period of time

Manual checking

After installation of columns it is a good practice to check the tightness of fittings manually both inside and outside the column oven. Do not over tighten any loose fittings as it can damage the ferrules or fittings

Soap solution checking

A soap solution is applied to the fittings and appearance of bubbles indicates leakages. This technique is convenient but is not recommended for the following reasons:

- Soap solution can enter the tubings and fittings and can lead to contamination of a column

- It is difficult to differentiate between the gas leak bubbles or boiling bubbles which can result from boiling of the test solution on high-temperature fittings

Leak Detectors

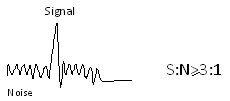

Leak detectors offer the ideal solution for leaks detection of GC columns and fittings. These are commercially available handheld devices and consist of a vacuum pump and a thermistor detector which measures the thermal conductivity of the gas drawn inside the handheld probe. Hydrogen or helium have greater thermal conductivities than the surrounding air and if present in the vicinity of fittings result in the response signal on the leak detector. Such detectors can also be used to check for leaks around hot fittings but it is not possible to check for leaks around fittings when GC oven fan is operating .Care needs to be exercised when taking such probes near electrical circuits or heaters.

In essence you can achieve a high degree of GC performance and reproducibility of results once you ensure freedom from leaks before running the GC system.

Good & precise