Why Graphite Furnace Atomization gives higher sensitivity over Flame Atomization

You may have all along heard that for higher detection limits you should opt for graphite furnace atomization instead of flame atomization. I presume that this was taken for granted without going into the reasoning behind the statement. The first step is to have a basic understanding of the fundamental concept of the two popular atomization techniques and then go into their benefits and limitations. Now you are ready to understand the reasons for the improved sensitivity of graphite atomization over the flame atomization.

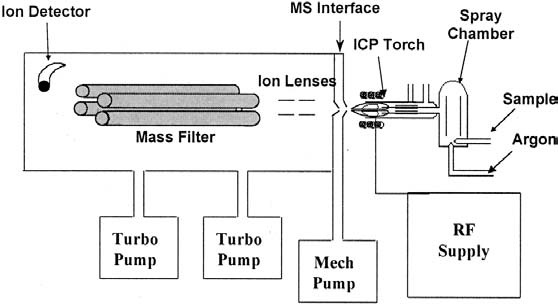

The sensitivity of graphite atomization almost rivals the limits attainable by ICP technique. In other words, you can normally reach ppm levels of detection using flame atomization whereas you can go down to ppb levels with graphite furnace atomization. In other words, the detection limits of some elements can be 10-1000 times lower when you switch over to graphite furnace atomization. The present article is an attempt to provide some justifications and further clarify the concept.

Factors contributing to the improvement of sensitivities

Efficient Sample introduction

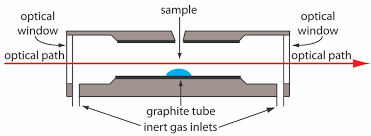

The robotic arm of the autosampler lifts a defined volume of sample solution, usually between 10- 50 µl, and introduces it into the graphite tube. The entire volume is available for atomization whereas in case of flame atomization more than 90%of the sample introduced into the mixing spray chamber gets drained out and only the remaining sample makes its way into the flame for atomization.

Extended time available for atomization

The entire volume injected into the graphite tube remains inside the sealed cavity till atomization and light absorption by the analyte atoms produced is over. This means that sensitivity improvement takes place due to the increased residence time required to complete the temperature program steps (around 1-2 minutes).In comparison, the analyte resides in the flame for only milliseconds(around 10-4 sec). This feature contributes to a larger absorption by the atoms produced inside the graphite furnace.

Higher Temperature in graphite furnace

The graphite furnace can be programmed for temperature increase at a very high rate of around 20000C and reaches the final temperature of around 30000C in a matter of 2 seconds and thereafter you can optimize the observation time to about 2 minutes. In contrast the temperatures of flames are usually lower(Air –Acetylene flames- 2100-24000C and Nitrous oxide- Acetylene- 2600-28000C) . Higher temperatures in the graphite furnace result in complete atomization.

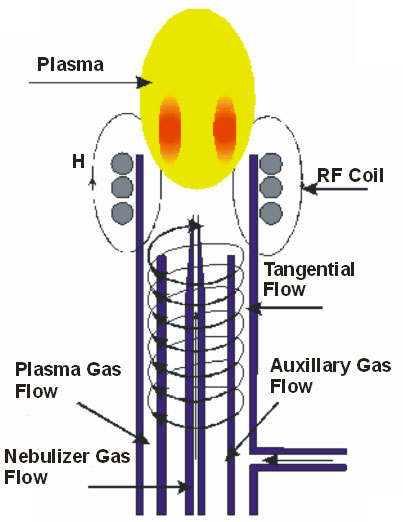

The inert environment inside the graphite tube

A constant stream of argon gas both inside and outside the graphite tube serves two purposes. Firstly the outside layer extends the life span of the tube by preventing oxidative environment at high temperatures and secondly the inner stream helps maintain an inert environment inside the tube. This helps prevent formation of stable oxides of refractory elements. On the other hand formation of stable oxides in flames leads to loss of analyte atoms and results in lower sensitivities.

Consistency of Atomization

In graphite atomization systems a power supply constantly monitors and compensates any line voltage fluctuations thus eliminating changes in heating rates due to voltage spikes .On the other hand, the conditions in the flame can change with variations in gas flow rate changes and changes in oxidant to fuel ratios .Such changes can influence the atomization efficiency of the flame.

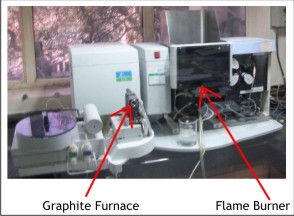

Hopefully the reasons for, warded will help you understand the reason for improved sensitivities when using graphite furnace mode. However, you should keep in mind the limitations of graphite furnace atomization and whenever sensitivity of detection is not a major concern flame atomization is a more convenient and economical option .It is for this reason that today all manufacturers of Atomic Absorption Spectrometers offer dual modes of operation and you can switch between the two operational modes conveniently.

Thank you Dr Deepak,

These materials are very helpful and useful as teaching and learning materials for my students at the National Polytechnic Institute of Papua new Guinea. Would appreciate sharing information on UV/Vis Spectroscopy, IR Spectroscopy , Turbidimetry, Refractometry and training materials on other instrumental techniques of chemical analysis.