Significance of Instrument Calibration on Quality of Results

You must have heard about the importance of calibration for laboratory equipment, but do you really understand its value? While this is a widespread and vital concept, there are people who still do not know its meaning or significance. Here, we will help you understand everything about calibration, from what calibration is to why is calibration important.

What Is Calibration?

Even before you get to the purpose of calibration in the laboratory, you first need to understand what this process is and why it is performed in various places.

Calibration is basically a procedure where you compare a Device Under Test (DUT) that has an unknown value with a known value’s reference standard. Through this, you can look out for any errors to further correct the device for accurate results.

Mostly, a calibration process is carried out when the machine or tool is new. As it just came in from the manufacturer, there are high chances of it being not showing perfect results. Calibration helps in correcting the machine so that no errors are found in its measurement values.

However, calibration is not a one time process. It is carried out again on a pre-determined frequency to check for errors that may occur due to the equipment’s wear and tear. Therefore, ensuring that the measurement tool shows the correct values all the time, and no procedure gets affected by it.

Calibration is usually crucial for the following industries:

- Laboratories: The purpose of calibration in the laboratory is to ensure all their tests are carried out properly, and no instrument causes any inaccuracy.

- Food Industry: The significance of calibration in the food industry is to keep their ingredients within standard limits and avoid any severe trouble for the consumers or their brand.

- Manufacturing Units: The importance of calibration increases for manufacturing units to maintain their processes, alarms, and systems. Plus, it helps in keeping away any injuries or loss of the workers.

Out of all, laboratory equipment calibration is what we will focus here on.

Why Is Calibration Important?

Instrument calibration is a vital activity without which your results cannot be relied upon.

Your lab may be equipped with the most sophisticated and costly instruments but if you do not calibrate them periodically, your results will have no significance.

Even low-cost instruments such as thermometers, pH meters, volumetric apparatus and ovens need to be calibrated from time to time to give reliable data.

Items like weights, measurement rods, volumetric apparatus which apparently do not seem to change with time also need to be calibrated against reference standards not just at time of purchase but regularly at defined intervals.

The need for such calibration arises due to changes in environmental conditions such as temperature, humidity and improper handling leading to wear and tear.

Sophisticated instruments running on mains power supply need to be more frequently calibrated because of involvement of several variables such as stability of power supply, usage lifetime of light sources, fall in efficiency of chromatography columns, normal wear and tear of mechanical parts,etc.

Instrument calibration is always against a traceable standard which is maintained under specified environmental conditions. Traceability to known national and international standardization bodies such as ISO, NIST, ASTM, BIS, BS, AOAC, etc is necessary.

At times it becomes cost prohibitive to procure the original standards so in such case reliable standards bearing traceability to original standards can be procured at a reasonable cost.

In short, calibration helps with making your measurement equipment more accurate according to the standards. In this way, you do not end up making any mistakes while carrying out any process. So your results are just as you want them to be, perfect. This is why calibration is important for different industries, and it must be carried out at specific intervals to avoid any trouble.

Calibration Frequency

It is necessary to calibrate all instruments and glassware before first use in the laboratory. Subsequently calibration is repeated as per intervals specified in the standard operating procedures on the basis of supplier recommendations. Outside the schedule calibration becomes necessary when an instrument is relocated even within the same laboratory, after a major repair or even if a new accessory is installed.

You should not worry about the cost associated with calibration because it is minimal in front of the importance of calibration. As calibrated equipment will show more accurate results, you can easily cut out on further costs of making errors with this process. So it is more of an investment rather than an expenditure, and you must carry it out at specific intervals.

Where to Calibrate?

Most of the instruments can be calibrated in-house but some instruments need periodic calibration by the supplier representative or an. outside calibration laboratory which is accredited by NABL for the required purpose.

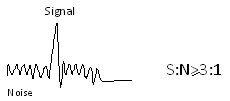

Again some calibrations are simple requiring calibration of output against a reference standard and there are others requiring calibration of different modules such as HPLC which requires separate calibration of light sources, pumps, injectors, etc. It becomes all the more important to keep record of all calibrations and such records should be preserved for time specified in SOP’s.

Who Can Calibrate?

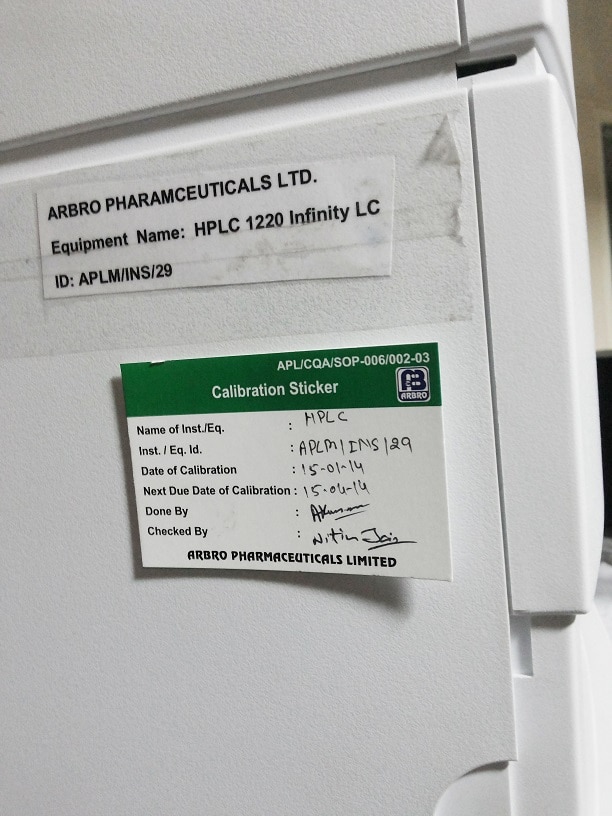

Instrument calibration is authentic only if it is carried out by person(s) authorized by the laboratory or by a third party. The person calibrating an instrument should put his signatures both on the calibration sticker and the calibration records.

Even in the general sense, calibration must be done only by a professional or authorized person. Otherwise, you can not ensure whether the calibration was successful or not. Therefore, failing the entire purpose of carrying out the process.

What to do if Instrument is Out of Calibration Validity?

Before using an instrument inspect its calibration sticker and ensure that it is within its calibration validity. If you find that the calibration date is over simply replace the calibration sticker with ‘ Instrument under Maintenance ‘ sticker and inform the concerned to complete the calibration before proceeding with its use.

Like instrument calibration the use of validated methods of analysis plays an equally important role and will be discussed in a subsequent article.

Please do let us know if you liked the article and share your valued comments.

It is necessary to perform the annual maintenance calibration.(AMC)

Dear Manoj,

Each instrument needs to be calibrated at intervals specified in the standard operating procedures.This interval will vary from instrument to instrument and is is not advisable to fix annual maintenance calibration on yearly basis.

I am personally grateful for being being on such a platform.I look forward to more

Can I calibrate a spectrophotometer UV-18oo (Shimadzu) in house or I need to call our supplier? What must be the frequency of Calibration for proper functioning of the above mentioned Instrument?

Dear Anupam,

Yes you can calibrate the instrument in your own laboratory using calibration absorption standards .There is no need for calling the instrument service engineer for the purpose.It should become a regular practice as stipulated in your Standard Operating Procedure.In case the frequency is not specified you may also take suggestion from your supplier.

Topic very interesting and educating

Thanks.