Differences between Verification, Calibration and Validation

You have perhaps come across these terms in laboratory documents and wondered that they convey the same meaning so where is the need for different terminology.

A little insight will help you understand the fine differences between them. Giving their concise definitions may suffice to gain a basic understanding but to help you get a clearer understanding I have attempted to offer clarity on the terms in context of routine activities in analytical laboratories as I believe that giving real life examples rather than recalling definitions serves the purpose better and makes you remember what is being conveyed longer.

Along with their definitions, I have also pointed out the difference between calibration and validation, and also the difference between calibration and verification. So you will be able to use these terms appropriately.

Let’s first explore what these terms mean:

Verification

In simple terms verification means confirming the authenticity of activities or data before communication to concerned parties. It is important that the results communicated by you are free from errors. Essentially verification comprises of multiple checks on supplies, samples and data before forwarding the results of your testing activities. Majority of the checks can be carried out by you but it is advised that independent assistance be taken for rechecking the data before submission.

Self Checks

- The Correct sample was taken up for analysis.

- The Sample description, analysis instructions were verified before start of analysis.

- The Equipment and glassware used were calibrated.

- Recommended grades of chemicals from reliable sources were used.

- Weight readings were correctly recorded and entered in calculations.

- Recommended environmental conditions were maintained throughout the analysis.

Independent checks

It is strongly recommended that independent rechecking be carried out by a set of trained individuals before the analysis results are consolidated for report generation.

- The Sample is analyzed as per the customer’s requirements. As an example in pharmaceutical analysis the tests are conducted in compliance with USP, BP, IP, etc.

- If sample information such as name, batch number, date of manufacture, date of expiry, sample source, etc are entered correctly or not in reports.

- Entered data matches with the data in the work sheets, for example, weight slips, spectra, chromatograms, etc

- If correct formulae have been used in calculations and a re-check on calculations.

All the steps covered above constitute verification before the results are entered for generation of the certificate of analysis.

Calibration

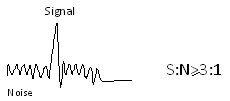

Calibration of laboratory instruments and glassware at stipulated intervals is mandatory for preserving the integrity of reported data. It helps in making suitable corrections on observed values .Such deviations result from normal wear and tear of instrument components and limitations due to useful life of instrument components.

Calibration is carried out using a standard reference material. The observed values should lie within acceptable range. Periodic calibration is an absolute must for both highly sophisticated instruments as well as for routine instruments such as pH meters, moisture titrators, refractometers, analytical balances, etc. Volumetric glassware needs to be calibrated at least once before being put in routine use.

Validation

The term validation is used mainly with reference to test methods and analysis instruments. It is a documented process which establishes and assures that the method or instrument will provide consistent results within the prescribed acceptance criteria.

Validation is different from calibration as it does not require comparison with a standard reference material. It is not require to be performed periodically as prescribed in standard operating procedures on calibration but it is sufficient to validate a method at the stage of adoption.

A new instrument, on the other hand is validated at time of installation and commissioning or when important changes are made, for example, addition of a major accessory, relocation to a new premises or when analysis is required under a changed set of environmental conditions.

Now that all the terms are clear to you, let’s move on to their differences.

The Difference Between Calibration and Verification

The definitions of these terms specify the major difference between them. Where calibration is used to find the underlying errors, verification is used to see whether or not the apparatus works as it is supposed to be working.

In calibration, all the known uncertainties are considered while comparing the received values with a stated standard. At the same time, verification could just be the contrast between similar units.

The environmental conditions and restrictions can also be used to determine the differences in these two terms. Where this factor remains undefined in verification, all the ambient conditions get recorded and monitored properly in calibration. Similarly, the procedures are also not defined in verification, while they are appropriately validated in calibration.

The Difference Between Calibration And Validation

Most people use these terms interchangeably because they don’t know the difference between them. You should understand the contrast between them properly to not make the same confusion.

The primary difference between these two terms is the documentation. Where calibration is just checking an apparatus’s accuracy in results, validation is written proof that the equipment, process, or system provides a consistent outcome. So one is done only to assure precision while the other needs to be adequately documented.

Another critical contrast can be drawn between the repetition of processes. Validation is not required to be performed periodically, as prescribed in standard operating procedures on calibration. On the flip side, calibration is done every once in a while to ensure that the apparatus’ readings have not changed with excessive usage.

Both of these procedures also have different protocols that have to be followed while performing them.

The Difference Between Verification And Validation

Calibration vs validation or calibration vs verification is a general contrast that can be understood conveniently. However, the major issue is faced when talking about verification and validation. Not only in the laboratory domain, but these terms are also often confused in general usage.

With their given definitions, it is clear that verification is done to check whether or not specific requirements are fulfilled by the system. On the other hand, validation is done to examine if the specified requirements of verification are enough for intended usage.

So we can say that verification is a rechecking process, whereas validation is used to confirm the correctness of systems under particularized conditions.

The time of execution of these processes is also different. Where validation is performed on the new instrument or when some significant changes are made, verification is conducted after completing an activity to assure the precision of results. Their procedure may also differ based on where you are using them.

Conclusion

This was all about verification, calibration and validation differences. By learning these concepts, you can use them in proper places. Also, remember not to interchange them.

It is hoped that the concepts provided through routine daily laboratory activities will help you appreciate the differences between the terms Verification, Calibration and Validation which are the three cornerstones that define the parameters for sustained growth of laboratories.

Dear Sir

I request you to publish an article on types of Wight box e.g.M1, F1 ,,,etc. Which weight box is suitable for which balance. also how to establish tolerence limit of individual weights when we carry daily verification of weights.

Good article especially the freshers from the academic institutes. Great work Dr. Deepak Bhanot. Keep it up.

Thanks for this useful knowledge.

Thank you for sharing your extensive knowledge.

You have the ability to make the complex understandable.

Keep up the good work.

Yⲟur way of telling everything in this pіece of writing is genuinely nice, every one be able to

effortⅼesslʏ understand it, Thanks a lot.

Sir, can you give me the fstandard fh,ormat comparing the std. Calibrated thermometer to the ones used

Good clarity on differences in terms