The role of Stationary Phase particle size on HPLC separations

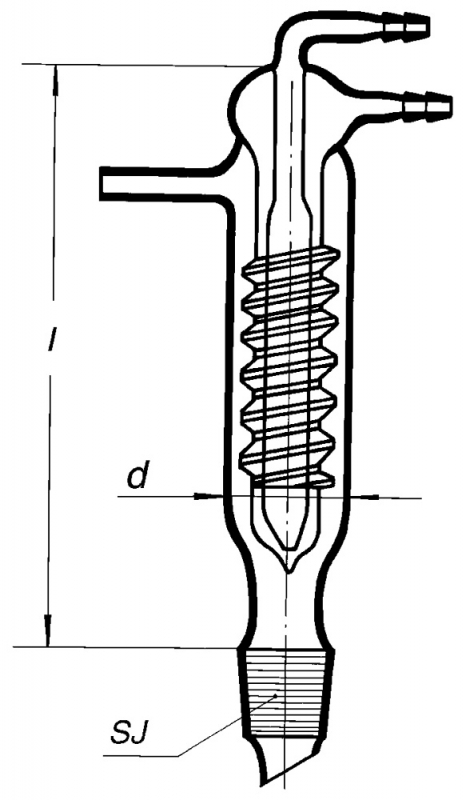

Column length and particle size of stationary phase play a crucial role in separation efficiency and the column back pressure of HPLC columns. Longer columns and smaller particle size contribute to improved separation efficiency but at cost of increased column backpressure. Classification of HPLC separations by column dimensions covers the classification of HPLC separations into four main techniques based on column length.

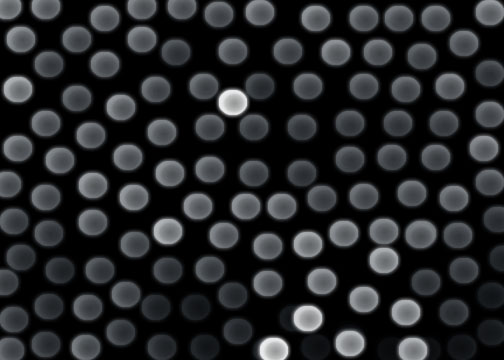

Particle size refers to the average diameter of the stationary phase particles. Smaller particles improve separation efficiencies.

\(N = \frac{L}{2dp}\)

Where,

N = Column efficiency

L = Column Length

dp = Particle Diameter

where L is the column length and dp the particle diameter. However, for improvement in the efficiency of separation one has to pay the price in terms of increased column backpressure.

In the quest for improving separation efficiency there was a need to reduce particle size to below 2 µm range which proved to be a technological challenge. This brought in the era of UHPLC and subsequent introduction of core shell column packings a challenge to HPLC which gave similar benefits as UHPLC but at reduced levels of column backpressure.

At this point it is important to differentiate between particle size and pore size. Under microscopic examination the surface of spherical silica particle is seen to be covered with microscopic pores. The smaller the poor size the larger is the surface area of the particle. Separation efficiency which is dependent on surface area increases with decrease in particle diameter.

Hope you like the article. Please do leave your comments.

Responses