Follow Maintenance Schedules to ensure high laboratory throughputs and reduce your Frustration

Adherence to maintenance schedules is a guarantee for trouble-free operation of your laboratory facilities. Instrument breakdowns upset your committed time frames for communication of results and add to your tensions when you are already running against time to meet the targets set by the top management.

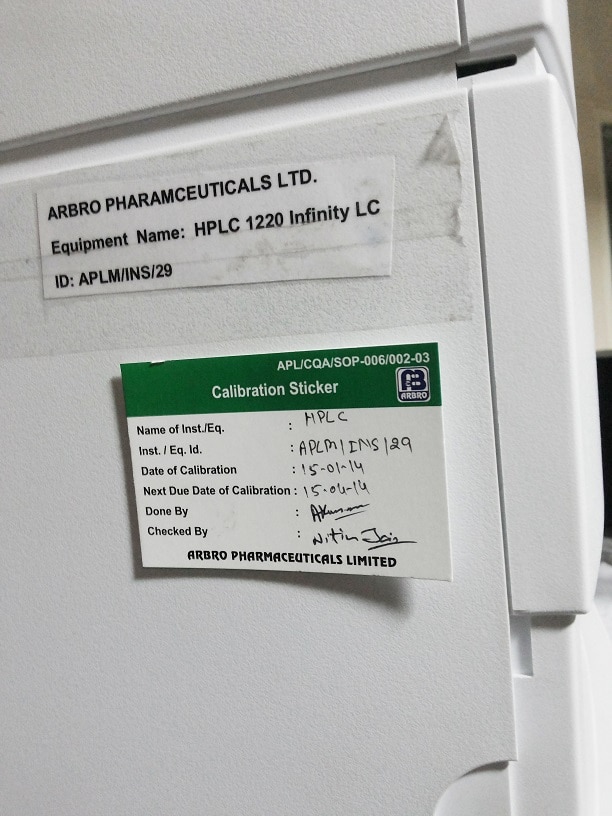

The earlier article on significance of calibration of instruments highlighted on quality of results that you achieve by calibrating your instruments. Periodic maintenance coupled with calibration is a sure road to success of laboratory operations.

Maintenance frequency

The periodicity of maintenance schedules cannot be decided on your whims and fancies. It should NOT be based on the following factors:

- Cost and sophistication of the instrument

- Useage

- Prohibitive cost involved in repairs

- Scheduling of maintenance only on days when work targets are low.

Maintenance of small low-cost instruments is equally important as any non working instrument irrespective of cost can lead to irritating delays when your results depend on them.

Who decides maintenance schedules?

It is the responsibility of the Quality Assurance Manager to lay down the schedule of maintenance of instruments and these schedules should be documented in the standard operating procedures. He in turn decides the schedules and specific maintenance procedures on the basis of recommendations of the instrument suppliers.

Responsibilities and Accountabilities

It is not justified to put the entire blame on the Quality Assurance Manager for non-adherence of maintenance schedules. Like any other activity it requires cooperation of the entire laboratory team. The responsibilities are proposed for a typical testing laboratory.

The implementation responsibility involves all persons including Analyst, Section In- charge, Manager- Technical, General Manager- technical and VP- Technical. The overall responsibility rests with the top management of the laboratory.

What are maintenance activities?

It is not possible to provide common guidelines for preventive maintenance as these are specific to each instrument but in this brief article some common tips are provided which you are sure to find useful

- Provide clean and dust free environment for all instruments

- Replace consumables which have a usage life such as light sources, filter cartridges, chromatography columns, septas, etc

- Hollow cathode lamps have a shelf life and even if these are not used for long it is essential to check their energy levels before using

- Clean air filters which provide air in gas chromatographs and atomic absorption spectrometers

- Clean orifices of optical and mass spectroscopic systems

- Check for oil level and condition of oil in vacuum pumps and compressors

- Cleaning of GC injector liners and syringes

- Washing of HPLC columns and conditioning of GC columns

- Physical inspection of bends and restrictions of peristaltic pump tubings

- Cleaning of check valves, mobile phase filters and leak detection in pump, column and detector cabinets

- Washing of HPLC pump to remove salt deposits to prevent abrasion damage to pistons, seals and O-rings after the use of buffered mobile phases

- Periodic cleaning of spray chamber, nebuliser and burner slits of atomic absorption spectrometers

- Cleaning of torch assembly, cones, drain system of ICP – MS and LC – MS

- Cleaning of water tank, heater rod, unrestricted water flow, compressor and inspection of salt deposits in water baths

Most maintenance activities are conducted in-house but certain specialised tasks require support of external agencies. It is advisable to enter into annual maintenance contracts with such agencies.

As discussed earlier it is important to follow the documented maintenance schedules and hold periodic reviews.In cases where periodic maintenance is not implemented it is necessary to go into the reasons and take corrective actions. Once again it is stressed that busy laboratory work schedules should not be accepted as valid reasons for non-implementation of maintenance schedules.

Hope you have liked the points covered in the article. Please do offer your suggestions and comments on this topic.

AAS, GC & HPLC Certificate Course Bundle

AAS, GC & HPLC Certificate Course Bundle  Certificate Course on AAS

Certificate Course on AAS  Certificate Course on GC

Certificate Course on GC  Certificate Course on High Performance Thin Layer Chromatography (HPTLC)

Certificate Course on High Performance Thin Layer Chromatography (HPTLC)  Certificate Course on ISO/IEC 17025:2017 - CPD Certified

Certificate Course on ISO/IEC 17025:2017 - CPD Certified  Certificate Course on Lab Safety

Certificate Course on Lab Safety  Certificate Course on Measurement Uncertainty in Chemical Testing

Certificate Course on Measurement Uncertainty in Chemical Testing

AAS, GC & HPLC Certificate Course Bundle

AAS, GC & HPLC Certificate Course Bundle  Certificate Course on AAS

Certificate Course on AAS  Certificate Course on GC

Certificate Course on GC  Certificate Course on High Performance Thin Layer Chromatography (HPTLC)

Certificate Course on High Performance Thin Layer Chromatography (HPTLC)  Certificate Course on ISO/IEC 17025:2017 - CPD Certified

Certificate Course on ISO/IEC 17025:2017 - CPD Certified  Certificate Course on Lab Safety

Certificate Course on Lab Safety  Certificate Course on Measurement Uncertainty in Chemical Testing

Certificate Course on Measurement Uncertainty in Chemical Testing

Responses