Potential Sources of Contamination and their control in Ultra- Trace level determination rooms

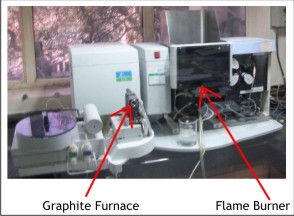

Ultra trace metal studies have evoked immense importance in the recent past due to increased awareness of potential risks of metallic impurities even at very low concentrations. This has opened up new avenues and applications of sophisticated techniques such as Graphite furnace AAS,ICP-OES, ICP-MS, Nuclear activation analysis , X-Ray Fluorescence and Isotopic Dilution Mass Spectroscopy. Trace analysis in ppm concentration ranges can be carried out using less expensive techniques but ultra-trace analysis in ppb or sub ppb levels require the more advanced techniques. Ultra-trace analysis has become indispensible in monitoring semiconductor materials, environmental samples and biological fluids.

Ultra- trace metal determinations require stringent laboratory environment controls as detection limits are pushed down to nano, pico or even femto gram levels. Air filtration with High Efficiency Particulate Air (HEPA) filters becomes a necessity. The Federal Standard 209D defines air quality and Class 100 standard (not more than 100 particles of 0.5μ size per cu foot) is acceptable in most clean air rooms. It has been observed that in spite of the stringent controls contamination can be introduced from sources such as laboratory furniture, apparatus, glassware, reagents and even chemists themselves.

The article will focus on potential sources of contamination and means that can be adopted to minimize if not totally eliminate them.

Metallic components and parts in instrument room

Metals on corroding can contribute greater problems than air particles so the steps suggested here can improve your results.

- Work benches should be made of ceramic tiles or wood with laminated surfaces

- Motor and blower exhaust should be enclosed in polypropylene housing

- Nuts and bolts should be replaced with HDPE ones and if not possible then coat them with an epoxy paint

- Room door should be made of wood and metallic fittings should be replaced with plastic fittings

- Room should be painted with epoxy paint.

- Round off room corners to prevent accumulation of dust in the corners and also to ensure turbulence free flow of filtered air.

Laboratory ware

Common borosilicate laboratory glassware is not suitable for ultra- trace metal analysis as it can release traces of Na, Al and B at both low and high pH values. Vitreous silica alongwith non- permeable plastic materials such as PTFE offer viable alternatives .Plastic ware can be cleaned with a non-ionic detergent like Triton-X followed by soaking in 1:1 nitric acid, 1:1 hydrochloric acid followed by washing with high purity water.

Timely analysis

The sample handling containers can also contribute to contamination and every effort should be made to reduce the time between sample collection and analysis. The contamination from sample container or loss of analyte to the container walls can be reduced by using vitreous silica or PTFE containers.

Contamination from Analyst

A chemist working in an ultra- trace metal determination laboratory needs to wear special protective clothing, gloves and head cover to prevent sample contamination from dandruff, hair, cosmetics, dead skin cells, etc.Coughing and sneezing can also introduce a large number of foreign particles.

Entry needs to be restricted in the clean room. Street footwear introduces a lot of foreign matter so special footwear covers need to be used inside the clean room. Shoe covers, gloves and protective clothing should be kept in a cubicle outside the clean room which is provided with UV illumination to kill bacteria and an air lock to prevent outside air entry. The chemist should wear the protective gear inside this cubicle before entering the clean room and leave it in the shelves in the same area before leaving.

Maintain cleanliness

The objective of maintaining cleanliness inside the room is to keep the particulate matter within the prescribed limits. Floors and walls should be mopped and cleaned at prescribed intervals and reagent bottles or other apparatus should also be wiped clean using lint free tissue soaked in a suitable solvent. All equipment taken inside the clean room should be cleaned with a vacuum cleaner in the airlock room prior to entry.

It can be seen that in spite of using highly expensive and sophisticated equipments or maintaining clean room environment the results obtained can show fluctuations which can only be controlled by taking adequate precautions on containing contamination from factors discussed in the article.

Hey There. I found your blog site web website using msn. This is a very well information. I will be sure to save it and come back to study more of your useful information. Thanks for the post. I’ll definitely comeback.