Factors deciding choice between Flame and Graphite Furnace Atomization in Atomic Absorption Spectroscopic Analysis

Atomic Absorption Spectroscopy has matured into a well accepted technique for analysis of trace metals in numerous application areas. It is routinely used for determination in parts per million to parts per billion concentration ranges with speed and affordable cost.

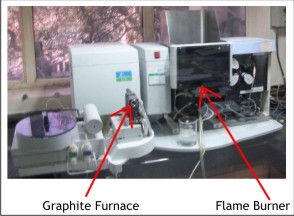

The two main techniques employed for sample atomization are flame atomization and electrothermal graphite furnace atomization. The benefits and limitations of the two atomisation processes were outlined in an earlier article Graphite Furnace Atomic Absorption Spectroscopy. The objective of the present article is to define the differences.

Flame Atomization

Flame atomization uses an air-acetylene or nitrous oxide – acetylene flame to remove the solvent and bring the element in the sample to ground state The ground state atoms absorb light from the hollow cathode lamp and produce signal proportional to the concentration of atoms in the light path.

Graphite Furnace Atomization

The technique is similar to flame atomization except that the flame is replaced by an electrically heated closed graphite tube having transparent end windows. The tube generates a cloud of atoms which is exposed to the light from the hollow cathode lamp. The higher the atom density and longer the residence time in the tube the lower will be the detection limit.

The benefits and limitations of the two atomization techniques are provided as tabulated data for ready reference.

| Flame AAS | Graphite Furnace AAS | |

| Capital Cost | Moderate | Higher |

| Operational Cost | Low | Medium |

| Sample Throughput | 15-20 sec per element | 3-4 minutes per element |

| Detection Limit | ppm – ppb levels | sub ppb levels |

| Tolerance for dissolved solids | 0.5 – 3 % | ~ 20% (Slurries) |

| No. of elements | ~ 70 | ~ 50 |

| Sample requirement | Large (few ml) | Small (few µl liters) |

| Unattended Operation | No | Yes |

| Interference :SpectralChemical (Matrix)

Physical (Matrix) |

Very FewMany

Some |

Very FewMany

Very Few |

An analysis of the tabulated comparison above shows that you have to select the atomization technique on the basis of considerations such as cost, sample throughput, required detection limits, etc. However fortunately most manufacturer’s today are providing Atomic Absorption systems with convenient interchangeable atomization options.

Please share your opinion and offer your comments.

how can to adjust the flame of aceylye gas and nitrouse gas to get goog reading

Hi Abdulqawi,

The sensitivitiy is dependent on the number of ground state atoms in the light path.In flame analysis you can rotate the burner or even adjust its height to get the maximum absorbance thereby giving improved sensitivity.

I have Thermo S-series atomic absorption spectrometer in my lab, but the flame is not coming up properly. That is, it always glow red and this is not useful for a good analysis. The air and gas were checked and they were in order.

What can I do to make it work sir. I mean, how can i troubleshoot the AAS.

Thank you sir.

Hi Nureni,

It appears that your burner head or burner is having some remaining contamination from previous analysis.Aspirate with 1% nitric acid solution for around 5 minutes and follow with same time with water.The flame should be free of the red glow.Even then if the glow remains check the purity of water as it may be having contamination of alkali/alkaline earth elements

I carried out an AAS analysis on aquatic macro-invertebrates to detect the level of heavy metals in them but most of my results in Ni, Pb, Cd and Cr came out very low while most of the result read 0.00 (ppm) except for zinc that has higher values. What could cause this?

First of all check the remaining life of your hollow cathode lamps. strongly suspect that they are nearing end of shelf life. If shelf life is not over or nearing expiry see if the procedure adopted is a validated one.

Hello Sir thank you for the article. However, I have a question.

Let’s say if I want to determine the Zinc content in fruit juice, should I use flame AAS or graphite furnace AAS, and why so? Is it due to the fruit juice or to the mineral content?

Choice of technique will depend on the expected concentration levels of Zinc. In case these lie in ppm range then flame version is fine. For lower concentrations you are advised graphite furnace atomization.

Helpful Content Sir, Graphite Furnace disturbing me, before reaching out here